cultivation

-

+86-514-8371 5668

-

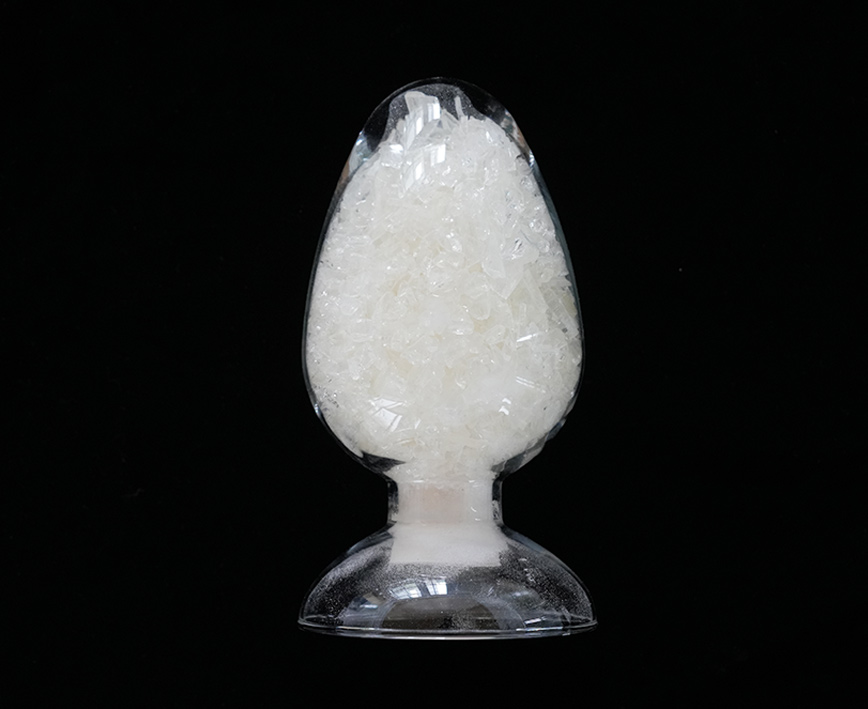

Deep history in polyester resin, and over 25 years of experience in R&D manufacturing, testing and export.

Our annual production capacity reaches 100,000 tons, which can meet the large-scale needs of customers.

A complete quality inspection manager system ensures the quality of the incoming material and the finished product.

We accept OEM&ODM services, customizing for customers, provide such as packaging services.

We have three kinds of casting process Silica Sol Casting, Lost Wax Investment Casting and Coated Sand Casting.

Our products are in line with international standards, and exported around the world, such as Europe, America, Japan, etc,.

We are only 35 kilometers away from Beilun Port, and the export is very convenient.

With a high degree of automation, automatic feeding, DCS automatic control system, automatic packaging and palletizing equipment.

We have a professional R&D team with strong R&D capabilities and recognized as a municipal engineering technology research center.

Supporting waste water and waste gas environmental protection treatment facilities to reduce pollution.

Practical Measures to Improve Coating Leveling (Flowability) 1. Formulation Optimization: Appropriate Resin Ratio Adjusting the mass ratio of polyester resin to epoxy resin to 90/10-95/5 can achieve good leveling while m...

Key Factors Affecting Shelf Life: 1. Temperature Control: Temperatures below 30°C significantly extend shelf life; temperatures above this accelerate the prepolymerization reaction of the resin. 2. Humidity and Moisture:...

What Core Application Scenarios Rely on Two-Component TGIC Polyester Resin? Two-component TGIC (triglycidyl isocyanurate) polyester resin is widely adopted in coating scenarios demanding high durability and corrosion res...