-

+86-514-8371 5668

-

Outdoor TGIC-cured polyester resin is a special polyester resin, which is characterized by the use of TGIC (triglycidyl isocyanurate) as a curing agent. It has fast curing ability and is environmentally friendly and harmless. The cured product has high hardness, good wear resistance, and strong chemical corrosion resistance. Outdoor TGIC-cured polyester resin is suitable for outdoor building products, high-gloss products, semi-gloss products, engineering machinery, and coiled steel powder.

| Polyester Resins For TGIC-Based Formulations | ||||||

| Type | Ratio | Acid Value (mgKOH/g) | Viscosity(pa·s/200℃) | Glass Transition Temp (Tg℃) | Curing Time (℃/min) | Properties |

| YZ9803 | 93/7 | 31-37 | 3.0-6.0 | ≥60 | 200℃×12′ | General-purpose weather-resistant type, can also be cured with HAA |

| YZ9803A | 93/7 | 31-37 | 5.0-8.0 | ≥58 | 190℃×12′ | High gloss, flex-resistant, fast cure, and more resistant to baking |

| YZ9803Ap | 93/7 | 31-37 | 5.0-8.0 | ≥60 | 190℃×12′ | High gloss,flex-resistant. fast cure, and more resistant to baking |

| YZ9803Z | 93/7 | 31-37 | 5.5-8.5 | ≥62 | 190℃×12′ | High gloss,flex-resistant, good performance, relatively high Tg |

| YZ9810 | 93/7 | 30-36 | 4.0-7.0 | ≥65 | 200℃×12′ | Building-grade materials, excellent weather resistance |

| YZ9820 | 93/7 | 30-36 | 3.0-6.0 | ≥64 | 200℃×12′ | Building-grade materials, good leveling |

| YZ9820D | 93/7 | 31-37 | 2.0-5.0 | ≥63 | 200℃×12′ | Good leveling, suitable for the preparation of low-gloss or high-gloss aluminum profile powder coatings |

| YZ9820Q | 93/7 | 28-38 | 2.0-6.0 | ≥63 | 200℃×12′ | Anti-direct gas baking, good leveling, good weather resistance, excellent outdoor stability |

| YZ9820M | 93/7 | 28-38 | 2.0-6.0 | ≥64 | 200℃×12′ | Can be used for spraying friction guns, good leveling, and excellent outdoor stability |

| YZ9830 | 93/7 | 30-36 | 4.5-7.5 | ≥66 | 200℃×12’ | Boiling resistance, fast reaction speed,building-grade materials |

| YZ9830A | 93/7 | 31-37 | 4.5-7.5 | ≥65 | 200℃×12′ | Boiling resistance, excellent weather-resistant, sand grain transfer |

| YZ9835 | 93/7 | 30-36 | 2.5-5.5 | ≥61 | 200℃×12′ | excellent leveling, good mechanical properties, building-grade materials |

| YZ9839 | 93/7 | 27-33 | 3.0-6.0 | ≥62 | 200℃×12′ | Sand grain powder coatings with low gloss can be prepared for, general industry |

| YZ9843 | 93/7 | 28-34 | 2.5-5.5 | ≥62 | 200℃×12′ | Suitable for flat, extinction powder |

| YZ9853 | 93/7 | 28-34 | 4.0-7.0 | ≥61 | 200℃×12′ | Suitable for extinction powder, sand grain, and building-grade materials |

| YZ9853L | 93/7 | 28-34 | 3.0-7.0 | ≥61 | 200℃×12′ | Good leveling,building-grade materials, can prepare low-gloss powder coatings |

| YZ9853A | 93/7 | 27-33 | 3.5-6. 5 | ≥62 | 200℃×12′ | Suitable for extinction powder, sand grain, and general industry |

| YZ9863 | 93/7 | 31-37 | 3.0-6.0 | ≥62 | 200℃×12′ | Suitable for sand grain, general industry |

| YZ9870 | 93/7 | 31-37 | 4.0-7.0 | ≥65 | 200℃×12′ | Boiling resistance, building-grade materials |

| YZ9890 | 93/7 | 30-36 | 2.5-5.5 | ≥58 | 200℃×12′ | Super weather resistance, transparent powder |

| YZ9898 | 93/7 | 30-40 | 3.0-7.0 | ≥60 | 160℃×20′ | Fast cured at low T, super weather resistance, good boiling resistance, anti-frost, resistance to direct burning oven baking |

| YZ9873 | 93/7 | 28-33 | 3.0-6.0 | ≥60 | 200℃×15′ | Suitable for sand grain, general industry |

| YZ9850 | 92/8 | 40-48 | 2.0-5.0 | ≥66 | 200℃×12′ | Wood grain transfer, boiling resistance, building-grade materials |

| YZ9880 | 94/6 | 27-33 | 5.0-9.0 | ≥66 | 200℃×12′ | Building-grade materials |

| YZ9817 | 93/7 | 30-38 | 2.5-5.5 | ≥56 | 200℃×12′ | Economy-grade |

Technical Key Points for Adjusting the Isocyanate Index The Isocyanate Index refers to the ratio of the amount of isocyanate actually used to the amou...

View MoreChoosing the right polyester resin formulation is crucial for ensuring product performance and environmental safety. For TGIC (triglycidyl isocyanurat...

View MoreCore Principles for Determining Curing Temperature and Time The curing process of isocyanate-cured polyester resin is primarily influenced by temperat...

View MorePractical Measures to Improve Coating Leveling (Flowability) 1. Formulation Optimization: Appropriate Resin Ratio Adjusting the mass ratio of polyeste...

View MoreAdvantages of Polyester Resins For TGIC Based Formulations in Improving Production Efficiency

In the modern coatings industry, improving efficiency is not only related to production capacity, but also an important manifestation of corporate competitiveness. Polyester Resins For TGIC Based Formulations has become the preferred material for many manufacturers due to its unique properties, especially in improving production efficiency. This polyester resin not only performs well in performance, but also shows significant efficiency advantages in the production process, meeting the needs of today's rapidly developing market.

Polyester Resins For TGIC Based Formulations is a special polyester resin that uses TGIC as a curing agent, mainly used in powder coatings and high-performance coatings. Its fast curing characteristics make its application in the coating process more efficient, and it can complete curing in a short time, reducing waiting time, thereby improving overall production efficiency.

Key factors for improving production efficiency

The biggest advantage of Polyester Resins For TGIC Based Formulations is its fast curing ability. Traditional coating curing processes usually take a long time, while TGIC resins can achieve curing effects in a shorter time. This feature means that the production line can proceed to the next step faster, thereby shortening the overall production cycle of the product and helping manufacturers respond quickly to market changes.

Since Polyester Resins For TGIC Based Formulations can achieve efficient curing at lower temperatures, it not only saves energy consumption, but also reduces costs in the production process. Production lines using this resin can significantly reduce heating time and energy expenditure, improving economic benefits.

An efficient curing process is not only about speed improvement, but also directly affects the quality of the coating. Polyester Resins For TGIC Based Formulations forms a uniform coating during the curing process, ensuring adhesion and wear resistance. This high-quality coating can reduce rework and scrap rates caused by coating defects, thereby further improving production efficiency.

Polyester Resins For TGIC Based Formulations is suitable for coating needs of various product types, including outdoor building products, high-gloss and semi-gloss products. This diversity enables the production line to quickly adjust the formula and process when facing different product needs, flexibly respond to market changes, and maintain efficient production.

Advantages of Jiangsu BESD New Materials Co., Ltd

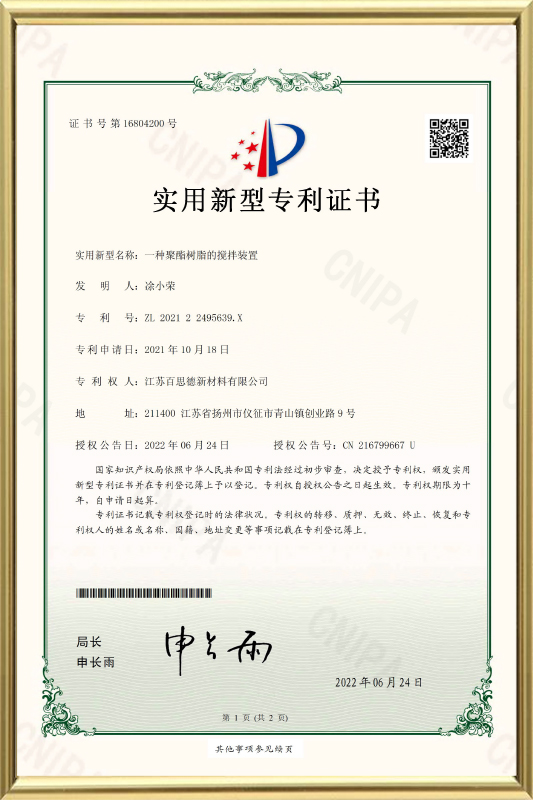

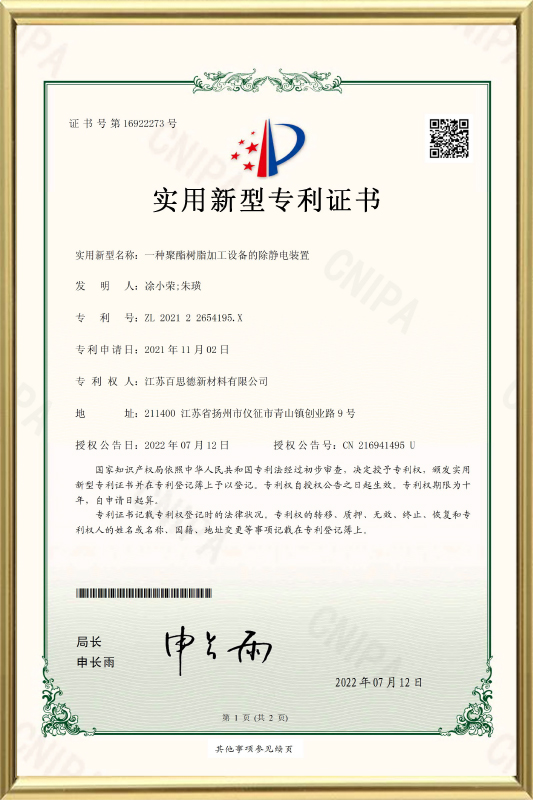

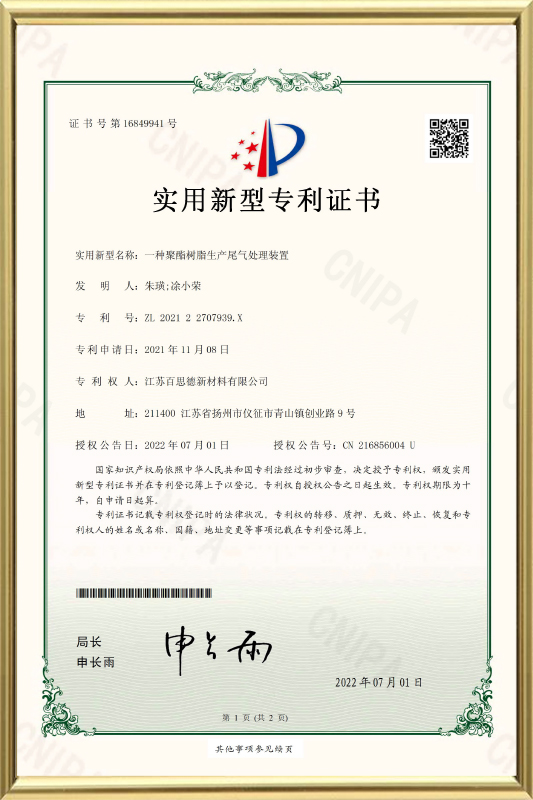

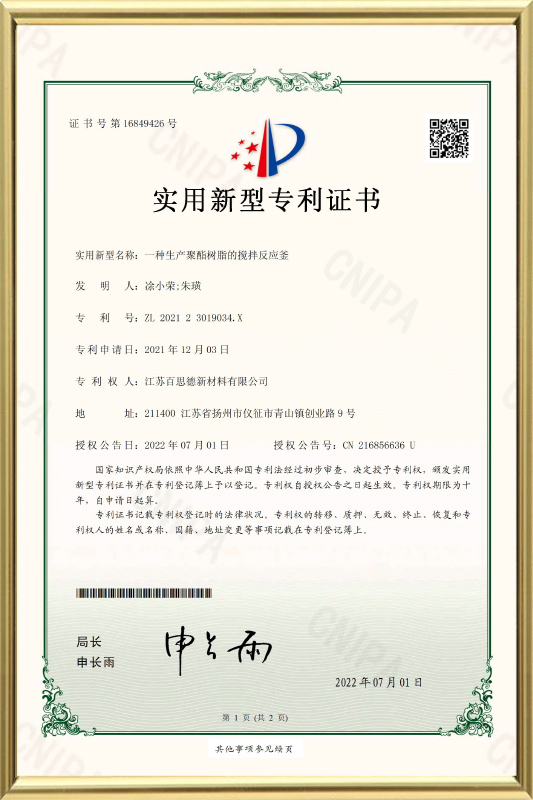

As a manufacturer in the polyester resin industry, Jiangsu BESD New Materials Co., Ltd has been committed to the research and development and production of high-performance polyester resins since its establishment in 1998. The company is located in Yangzhou Chemical Industry Park, Yizheng City, Jiangsu Province, and has advanced automated production lines and a professional R&D team.

BESD's Polyester Resins For TGIC Based Formulations products are highly recognized in the market for their efficiency performance. Through strict quality management and continuous technological innovation, BESD ensures that its products not only meet industry standards, but also provide strong support to customers in improving production efficiency.